COMPANY

Yunsung F&C, growing based on quality and technology.

Quality Management Program

Always striving to achieve customer satisfaction through the best quality.

Quality Management Policy

Please move the screen left and right.

Please move the screen left and right.

Quality Management System

-

Policy

Top Quality Management

Direction for

Quality Assurance

-

Quality Manual

YS QAM-100 : ISO9001 : 2008

YS QAM-200 : ASME U

YS QCM-300 : CSEL

-

Quality

ProcedureYS QAP-1000

: Quality Assurance Procedure

-

Documentation

Quality Verification Data

Design Related Records

Achieving customer satisfaction through the best quality service

Quality Management Flowchart

Please move the screen left and right.

Please move the screen left and right.

Design Quality Control

-

STEP 01

Project Initiation

- Establishment of Design Execution Plan

SPEC. Review

-

Project Project Initiation Result

Project K. O. M

-

STEP 02

Establishment of Design Concept

- Approval/Regulation Review Document

SPEC. Review

-

Establishment of Design Policy

Design Meeting

-

STEP 03

Detail Design (FA stage)

- Technical Review

Preliminary Order Documents

Approval Documents

-

Preparation ofFA Documents

Quality Check (1st round)

-

STEP 04

Detail Design (AFC stage)

- AFC Documents

B/M Outputs Specification Documents

Customer Requirements

-

Preparation of AFC Documents

Quality Check (2nd round)

-

STEP 05

Drawing Changes (Revision & F/U stage)

- Revised Documents Reflection of Customer Feedback

-

Quality Issue Documents

Quality Meeting

-

STEP 06

Drawing Changes (As-built stage)

- As-built Documents Approval Documents

-

Submission of Project Outcome

Submission of T/O Document

-

STEP 07

Project Close Out

- Final Document Submission

V-Model Approach for Equipment Suitability Evaluation.

The V-model is primarily used to manage the validation sequence for manufacturing and support equipment such as vessels.

In the V model, the documents for DQ (design qualification) and the protocols for IQ (installation qualification), OQ (operation qualification),and PQ (performance qualification) are linked together. Commissioning

Please move the screen left and right.

Please move the screen left and right.

Suitability Qualification of Vessels

Vessel types have a direct impact on products, and some vessels play an auxiliary role in the process. The decision to conduct only a commissioning testor to perform a suitability evaluation depends on its intended use. Risk assessment can be used to make such decisions.

- Solution formulation/mixing vessels

- Synthetic vessels

- Injection solution

- IBC/Blender

- Bio and culture vessels

- Purified water/distilled water storage tanks

Representatively, the types of vessels that require Suitability Qualification evaluation are as follows

Please move the screen left and right.

Please move the screen left and right.

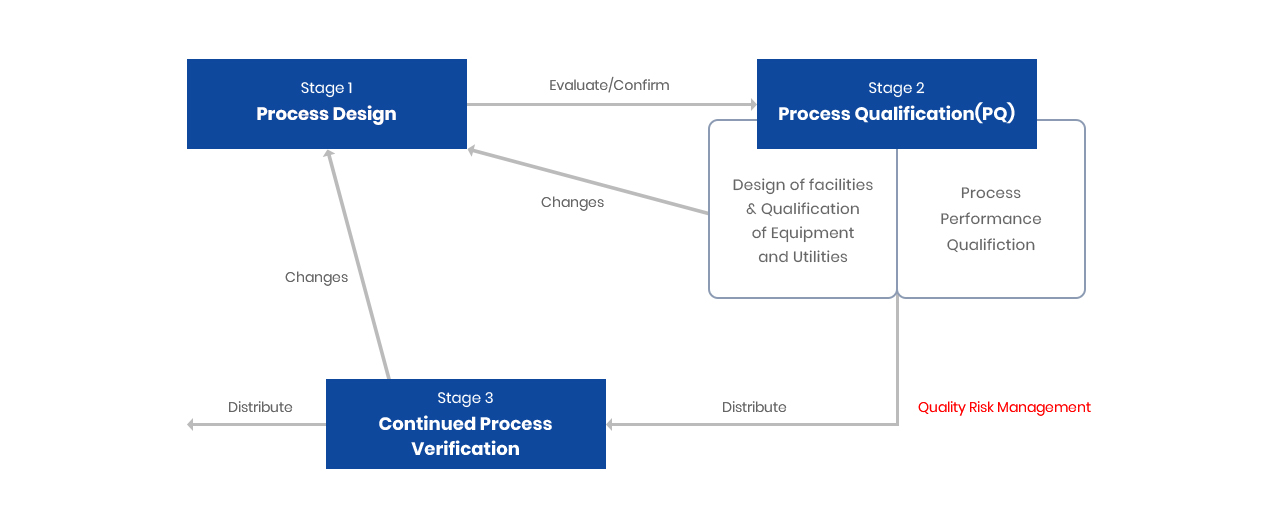

Process Validation Flowchart

Please move the screen left and right.

Please move the screen left and right.